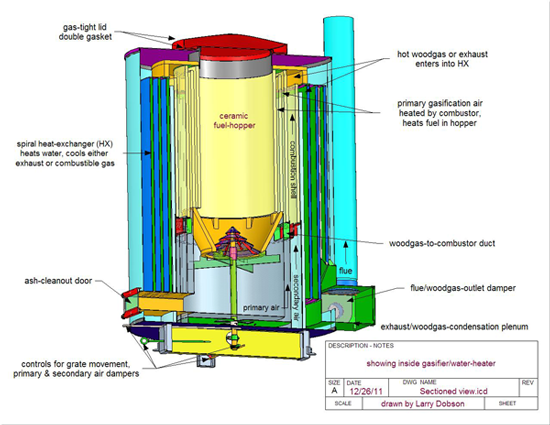

Larry Dobson, December, 2011

For the plans and other detail of this gasifier/water heater check see Larry Dobson's web site:

http://www.fundamentalform.com/html/biomass_gasifier_breakthrough.html

Larry has been working on gasifiers for more than 30 years. His other work has been of a more traditional design. This idea is a home water heater with a high efficiency and a good turn down ration 20/1 and the ability to use high moisture fuels - provided that they are properly sized and fed. This has a manual design, it is still a prototype, but there is room for electric control and other improvements.

These are some of the highlights (quoted from Larry's web site):

"THIS GASIFIER/FURNACE IS DESIGNED AROUND THESE CONSIDERATIONS, WITH THE FOLLOWING FEATURES:

- The hopper and entire construction is cylindrical, creating more even feed and flow, less thermal stress, simpler construction, more reliable seals, thus the name “Roundy”.

- When burning the gas to heat water, the generated gas is burned in a concentric combustion shell, which feeds heat to the incoming air and fuel in the hopper, augmenting the calorific value of the produced gas, thereby requiring less air for more gasification of a higher quality gas, which is mixed with preheated air and burns super-clean in the combustion shell.

- Highly preheated gasification air is introduced to the preheated fuel around the base of the hopper, where it is burned and gasified, creating a steady-state fuel feed without disruption of the fuel. Residence time of all heat transfer and chemical reactions can be much greater than conventional practices, which greatly expands fuel options.

- Any fuel that will fit in the hopper and produce a combustible gas can be gasified ~ logs, chips from the tree trimmers, bark, sawdust, corn cobs, leaves, wood-, straw-, municipal solid waste-pellets, green and wet biomass (up to 2/3 water), household and farm waste, etc. Since this first version of the gasifier has a thin-shelled ceramic hopper lining, large heavy chunks of fuel should not be dropped in, especially without a cushioning coal-bed. Testing of this prototype will indicate whether a lighter, thinner stainless steel hopper will withstand the internal temperatures.

- Although this design with all the interrelated heat-feedback features is where I want to begin testing, you may wish to begin with a simpler version. Many variations and degree of refinement are possible, beginning with a simple insulated inner shell and moving conical grate configuration, or reducing the size of the heat-exchanger or air preheater. However, adding air-preheating and gas-cooling shells will substantially improve performance.

- This is no longer a patentable design, as I hereby release it to the public domain, in the hopes that others will implement these new design features and do the R&D work necessary to bring biomass gasification to a new level of practicality, offering a greater contribution to decentralized alternative energy technologies.

- This first prototype is experimental, with no guarantees, although past experience and flow analysis says it should work great. It is not a simple vehicle-size unit made from scrap metal from the junk yard, although those and other options should be explored by you backyard tinkerers. I have designed it to test several new concepts that could be the foundation for a new approach to gasification.

"