from Yury Blagodarov, December 2011

Mobile pyrolysis plant is designed not only to produce charcoal, but also for the production of birch tar from birch bark, automotive recycling tires into liquid fuel. As we know the demand for charcoal depends on the season. In the spring and summer of charcoal taken better in winter, worse. Birch tar is always in demand, but in small quantities. His take veterinary hospitals, pharmacies, some enterprises Chemical Industry. On tire recycling products is a constant demand for steel cord, coke (with a mixture of soot). For liquid heating oil needs a constant source of sales. In addition, the tires are not always in large quantities.and for their storage needs more space. Due to the versatility you can optimally allocate mode setting so that it is not idle, and there was a constant sales.

In the production of charcoal in the mobile uglevyzhigatelnyh facilities for people working in them, you have to manually unload the charcoal, wood dust to breathe, which affects their health.

Mobile uglevyzhigatelnye installation with a few exceptions, much smoke, emit dymogazy, which contains a number of not dogorevshih combustibles.

The most advanced facilities at the lower emission of harmful substances into the atmosphere from stationary pyrolysis systems NRM Polikor, Ekolon. The process of charcoal production is mechanized.

Of mobile pyrolysis plants can be noted uglevyzhigatelnyh pyrolysis furnace uglevyzhigatelnuyu MUL2S, but it is necessary to exit the charcoal by hand. You also need time to cool down the furnace.

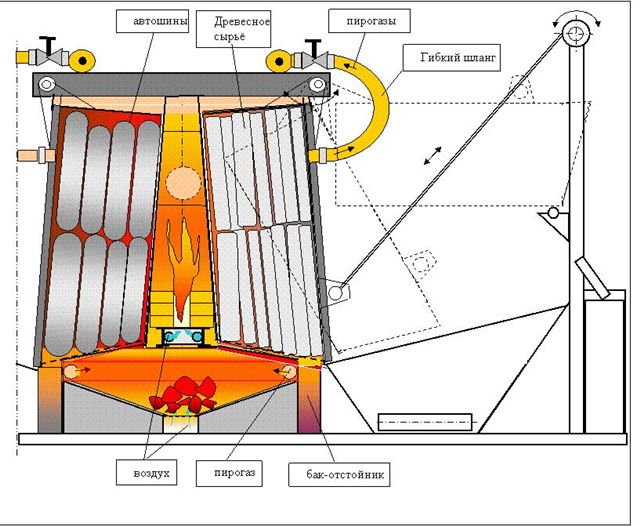

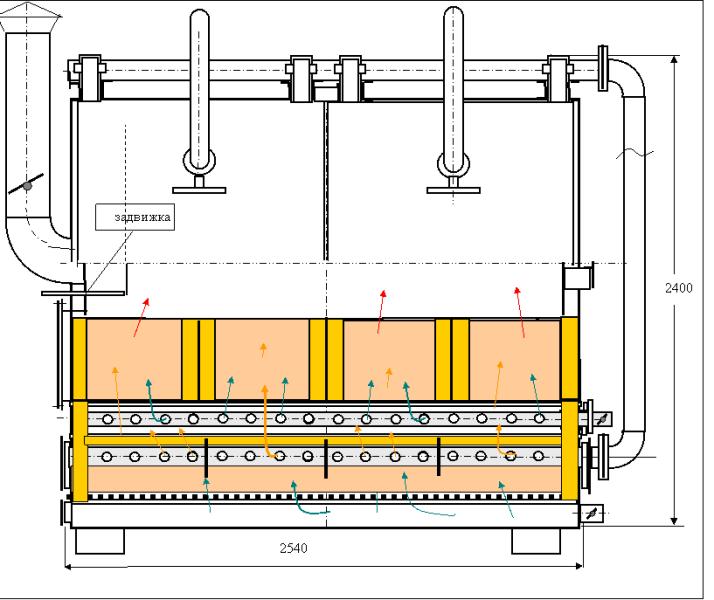

Proposed for the production of pyrolysis for charcoal burning mobile unit consists of several sections hoppers (retorts).Bunkers are closed tightly. They are mounted on hinges and can be rotated in a vertical plane. So, if you want to unload the charcoal ready, simply turn the tank and hold it in front of the bunker-settler. Next, open the door in the side hopper and charcoal thrown out himself in the bunker-settler. Then, the charcoal in a bunker-sump cover asbotkanyu to spontaneous combustion of coal was not. Just a few minutes and the hopper is ready for the next boot .. And load it as follows: hand winch or two people turn the hopper (retort) in the vertical plane to the horizontal position and lock in this position, putting on scarves, a hopper tube. Next, you can start loading firewood or tires, processed tires if for the production of liquid fuels. I note that the processing of tires need additional equipment for the condensation of combustible gases and liquid filtration otopliva.

In the mobile pyrolysis unit best burn combustible gases. Saving wood combustion in the combustion chamber reaches up to 25%. In addition, in the process of heating boilers and carbonation involves pyrolysis gases leaving when shrinkage drevesiny.Na bins installed three-way valves. When an intense parovydelenie, steam is expelled through a three-way valve.

The process of starting the boiler in the following: first, melted wood in the firebox, and then the boiler works and heats the hopper combustion of pyrolysis gases coming out one by one with each bin. For the afterburner pyrogas provides secondary air supply to the nozzle located below the combustion chamber.

The design of the installation is designed so that you can get close to any location and make repairs in places most high-temperature steel sheets are replaced by chamotte plate. All heat-stressed place of the combustion chamber are thermally insulated. Steel structures are not subject to deformation.

Details of the construction of this facility is described in etogm site:

http://blogs.mail.ru/list/user-05/