Submitted by Erin Rasmussen on

Making Charcoal from Dr Jury Judkevitch

Submitted by Visitor (not verified) on

Polykor Furnace

Submitted by Erin Rasmussen on

RADHE Renewable Energy Development Associates (2005)

Submitted by Tom Miles on

Agni Energy Services (P) Ltd Projects

Submitted by Erin Rasmussen on

Gasifier and Poly Digester Center for Agricultural Research and Training (CelAgrid)

Submitted by Erin Rasmussen on

The Making of Wood Vinegar

Submitted by Erin Rasmussen on

MDE Dezentrale Energiesysteme GmbH

Submitted by Erin Rasmussen on

GAS-L: Re: pressurized combustion

Submitted by Visitor (not verified) on

GoBiGas, EQTEC Iberia, Cortus (WoodRoll), Xylowatt among others join REGATEC 2015

Submitted by Jorgen Held on

The First Grid-Connected 500 kWe Biomass Gasification System deployed at Isla de la Juventud. Cuba.

Submitted by Erin Rasmussen on

Portable Syngas Analyzers

Submitted by biolists on

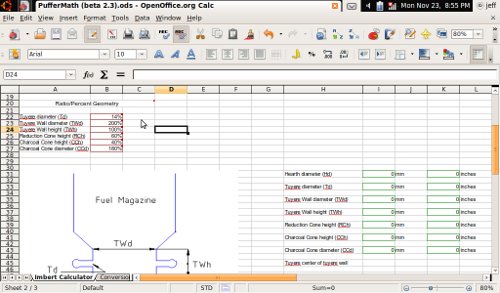

PufferMath

Submitted by Jeff Davis on

Gas-of-Fire 1000 Videos - 2

Submitted by Erin Rasmussen on

The Making of A Woodgas Generator -2

Submitted by Erin Rasmussen on

Modular Biomass Gasification - CHP installation -2

Submitted by Erin Rasmussen on

Cow Manure Densification And Gasification- Converting Cow Manure Into Energy -2

Submitted by Erin Rasmussen on

2nd International Conference on Application of Biomass Gasification

Submitted by Erin Rasmussen on

Thames Valley energy Visit to Biomass Engineering, Warrington

Submitted by Tom Miles on

Development of Gasification System Fuelled with Oil Palm Fibres and Shells

Submitted by Tom Miles on